Additive Advantage: Why Foundries Are Turning to 3D Sand Printing

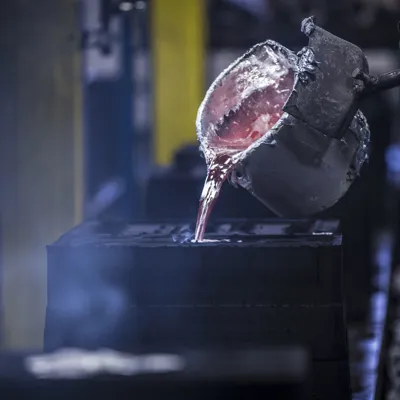

From car, airplane and rocket components to parts used in kitchen appliances and plumbing fixtures, products created by metalcasting are ubiquitous in modern life and support our daily activities in big and small ways. The manufacturing process depends on precise engineering to create these complex, high-strength products. At a high level, the steps are the same as those involved in making a candle by pouring melted wax into a shaped plastic mold. Molten metal is poured into a specially shaped cavity—called a mold—and allowed to cool and solidify. After cooling, the mold is broken apart to reveal the finished casting.

In one common metalcasting process, the mold is made from sand that is packed into what is called a flask. A pattern, or three-dimensional model of the object to be cast, is used to create the negative space that will be filled with metal. The pattern can be made of wood, plastic or metal. Cores may be placed inside molds to create internal cavities or hollow sections within the final product, such as channels or passageways.

While the average person may never see these molds or the foundries that create them, their output is all around us. Metalcast parts are found in:

- Engine blocks, heads, brake rotors and drums and exhaust manifolds

- Aircraft and aerospace components

- Trains and subways

- Mining and construction equipment

- Wind turbines and nuclear plants

- Medical devices and appliances

- Fire hydrants, pipes and valves

- Defense systems

The metals used are just as diverse—ranging from iron, aluminum and steel to grey iron, ductile iron, magnesium, zinc and copper-based alloys. The parts are often geometrically complex, requiring both high precision and strength.

3D Printing Changes the Game

In traditional metalcasting, the patternmaking process is costly and time-consuming. Patterns can be large and cumbersome. They take time and skill to produce and must be stored and protected for repeated use, adding to a foundry’s costs and risk. In addition, even slight modifications to the design of the part being cast require producing a new pattern.

However, with the advent of additive manufacturing and 3D printing technology, foundries can now produce cores and molds without traditional tooling, providing significant advantages. Because no physical pattern is required—only a digital design of the core or mold—foundries can produce cores and molds within a day of receiving the design files. The speed and agility of 3D printing are game changers for producing custom parts, producing small batches, making especially complex parts, quickly producing a prototype or modifying an existing design.

The 3D Sand Printing Process

Foundries use 3D sand printers to build cores or molds layer by layer. Also known as binder jet 3D printing, this process uses specialized foundry sand and a liquid binder. Like an inkjet printer, the machines’ jets precisely apply the sand and the binder, which bonds the sand particles together.

With 3D sand printing, foundries can achieve new levels of speed, precision and design complexity.

Compared to traditional processes, 3D sand printing offers several advantages:

- No tooling required: Eliminate the time and cost associated with pattern and core box fabrication.

- Speed: Cores and molds can be produced from a design file in days instead of weeks or months.

- Design complexity: Intricate core geometries that once required multi-piece assemblies can be printed as a single component.

- Flexibility: 3D printing is ideal for proof of concept, rapid prototyping and low- to mid-volume production.

- Waste reduction: With digital design and recyclable sand, 3D printing can support more sustainable foundry operations.

This combination of performance and efficiency is why more foundries are integrating 3D sand printing into their manufacturing process. Adoption is growing rapidly. An estimated 25 percent of U.S. foundries are either investing in 3D sand printing themselves or using the technology through outsourcing, and that number is expected to rise sharply. Covia has the expertise to help foundries capitalize on this emerging technology.

Covia’s 3D Printing Expertise: More Than Just Materials

Covia is more than a sand supplier. We’re your strategic partner, helping foundries navigate the transition to additive manufacturing. With decades of experience in the foundry market and a deep understanding of mineral science, we help customers optimize their printing process from end to end.

What sets Covia apart:

- In-depth technical support: Our experts and distribution partners can make sand recommendations, help adjust printer settings, troubleshoot binder performance and improve dimensional accuracy.

- Platform agnosticism: We learn about your specific challenges and customize solutions to work with any 3D printer platform.

- High-volume supply and logistics: Our strategically located network of foundry sand facilities produces consistent, quality-controlled sand ready for nationwide distribution.

- Performance validation: We offer standard and custom analytical testing through our Covia Analytical Services Laboratory.

- Customization: We tailor sand solutions to meet specific GFN, pH and ADV targets based on your application.

“You’re not just buying sand,” said Mike Kline, Director of Metals and Foundry at Covia. “You’re buying the confidence that comes with using sands that are proven and used every day by foundries and core shops across North America.”

INCAST® 3D: Sand You Can Rely On

In 3D printing, consistency is everything. A slight variation in sand quality, from grain shape to pH, permeability or turbidity, can impact printer performance and the final product. Covia’s INCAST® 3D Printing Foundry Sand is specifically engineered and produced to provide consistency and performance in 3D sand printers.

INCAST 3D delivers:

- 99%+ high-purity, round quartz sand

- pH-neutral chemistry and low turbidity for clean binder interaction

- Superior roundness for optimal packing density and surface finish

- Consistent performance across printing platforms and resin systems

- Compatibility with both traditional and additive manufacturing

“At Covia, consistency is paramount—from load to load, railcar to railcar,” said Kline. “From chemistry to grain distribution, our sand is stable and reliable.”

The Right Sand for the Job and the Partner to Back it Up

With Covia’s foundry sand products, customers receive a high-quality product and the support to take on 3D printing with confidence. With proven expertise, superior sand and unmatched support, Covia is your partner for adopting or advancing this transformative technology.

Contact us today to learn more.