Multi-Purpose Ground Crystalline Silica

SILVERBOND®

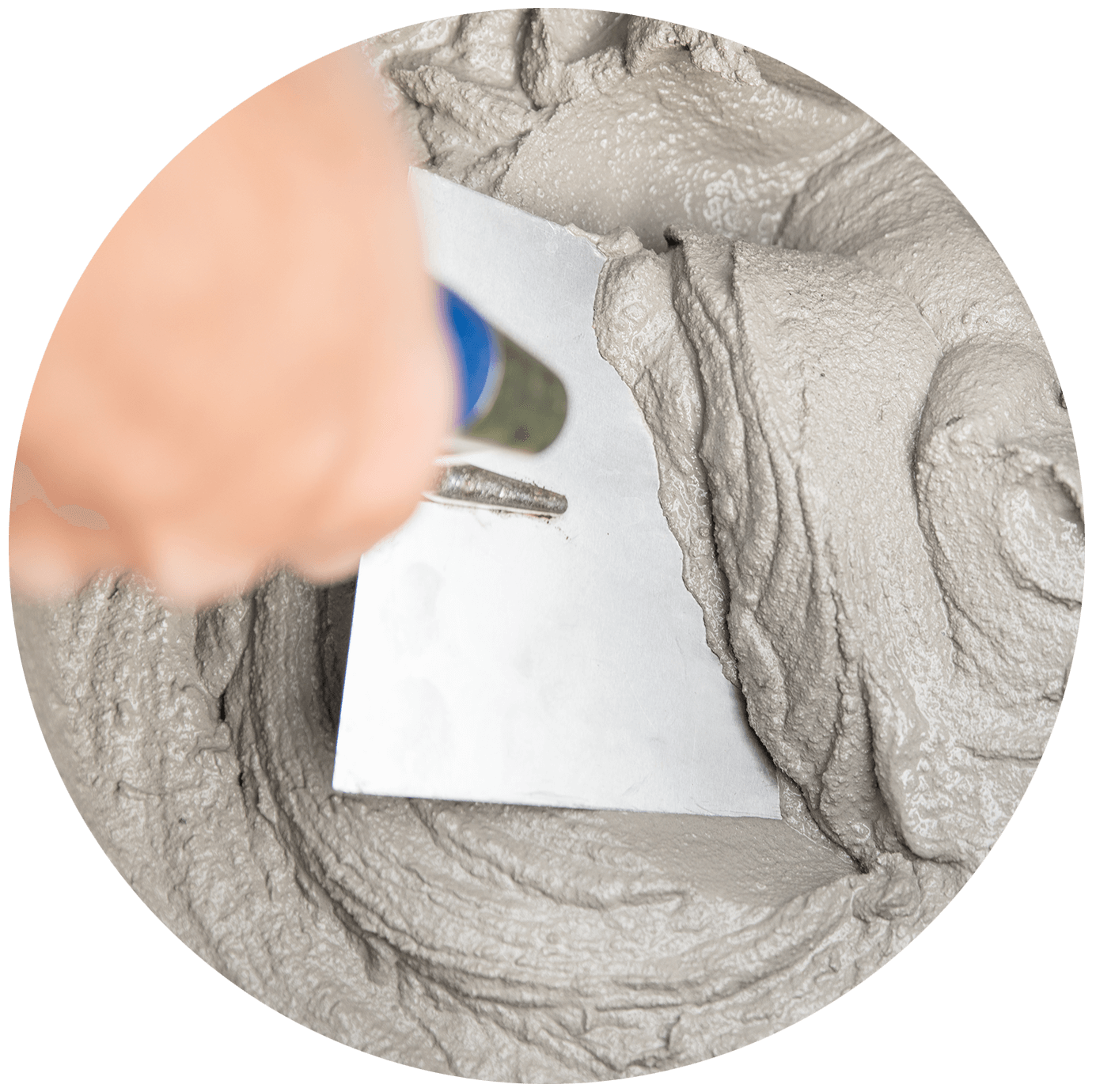

In demanding construction environments, performance failures aren’t just inconvenient; they can also increase costs and contribute to delays. When you’re formulating cementitious systems, epoxy grouts or insulation materials, you need a filler you can trust to perform under pressure, in every condition, and in any mix.

Covia’s SILVERBOND® meets that challenge. Manufactured from high-purity quartz and engineered for consistency, SILVERBOND is a chemically inert, thermally stable and nonreactive ground silica designed to deliver strength, stiffness and durability without interfering with chemical systems or degrading in harsh conditions.

Product Highlight

SILVERBOND is a high-purity, multi-purpose ground crystalline silica designed for advanced construction and industrial applications. Mined from premium quartz and processed under Covia’s rigorous QIPSM quality assurance protocols, SILVERBOND delivers structural integrity, chemical purity and particle uniformity for every application, every time.

Features

- Chemically inert and nonreactive

- High structural integrity

- Low surface area and oil absorption

- Uniform particle size distribution

- Produced from high-purity quartz

- Uniform performance across grades

Enhanced strength:

· Enhances strength and stiffness in cementitious systems.

High loading:

Allows high filler loading without compromising performance.

Extreme conditions:

Withstands extreme thermal conditions.

Prevention of chemical interference:

Prevents chemical interference in multi-component systems.

Consistency:

Delivers predictable, consistent results across production batches.

Cement, concrete and precast formulations.

Epoxies and elastomeric systems.

Fire-retardant and insulating materials.

Electrical potting compounds and assemblies.

Mortars, grouts and polymer concretes.

Chemical inertness

pH neutral

Nonreactivity

Structurally sound

Going to the Extreme

Concrete is the most widely used material in construction because of its structural performance, but concrete deterioration is a major challenge in regions that experience extreme weather conditions. Secondary cementitious materials can be critical for concrete durability, longevity, cost, workability, strength and as a mitigation method to reduce alkali-silica reactions that lead to premature concrete failure.

High Temperatures

Although some fillers break down when exposed to extreme heat, SILVERBOND doesn't. Its thermal stability and chemical inertness make it an ideal choice for fire-retardant materials, high-performance concretes and heat-resistant industrial products, where reliable performance under sustained high temperatures is critical.

Freezing Temperatures

In cold climates and freeze-thaw environments, fillers that absorb moisture can compromise the durability of the material. SILVERBOND’s low porosity and consistently uniform grading help prevent cracking, shrinkage and material degradation—keeping structures strong even in sub-zero conditions.

Alkali-Silica Reactions

Alkali-silica reactions (ASRs) are a major cause of cracking and premature failure in concrete. SILVERBOND’s high purity and chemical stability significantly reduce the risk of ASRs, supporting long-term durability in concrete and precast applications, especially in projects where longevity is non-negotiable.

Contact Covia today at 1.800.243.9004 or Sales@CoviaCorp.com, or click to fill out this form.