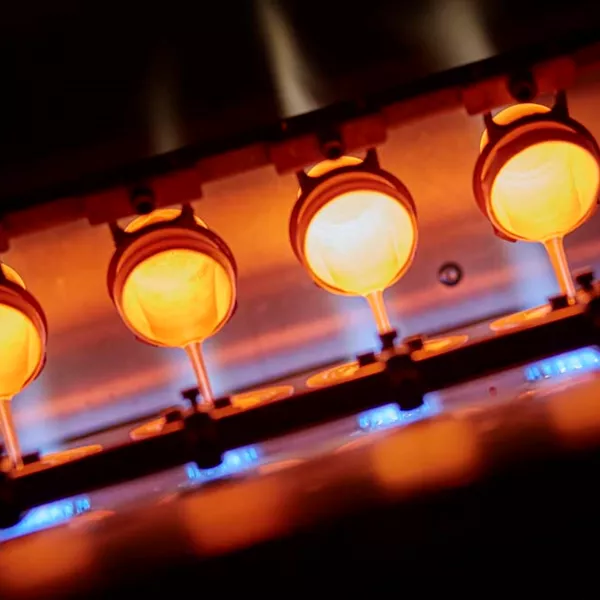

High-Purity Glass Sand

GLASSIL®

GLASSIL® high-purity glass sand is produced from whole grain crystalline silica sand. Consistent size distribution through accurate classification of coarse and fine grains offers glass manufacturers a uniform melt, reduced incidence of foaming and formation of scum, and optimized mixing integration with all batch components.

Available throughout North America, GLASSIL consistency and uniformity is ideally suited to standardize incoming raw materials and to optimize batch economics in the production of flat and structural glass, container glass, tableware and decorative wares, fiberglass and silicates.

Features and Benefits

- Made from high-purity, whole grain crystalline silica sand

- Produces uniform melt and optimized mixing integration

- Ideal for a variety of glass applications

GLASSIL® DST®

We are committed to creating products and services that enable our customers to work with the highest professional and environmental standards. GLASSIL DST treated sand with Dust-Suppression Technology is the latest product that furthers our mission.

DST Dust-Suppression Technology enhances worker safety by significantly reducing potential exposure to silica dust. Our technology – combined with dust/vacuum collection equipment and PPE best practices – is an important part of glass manufacturers’ engineering control plan for compliance with OSHA’s respirable crystalline silica regulations.

Features and Benefits

- Reduce total airborne dust throughout the entire manufacturing process

- Sand-melting characteristics require no change of glass batch formula

- Maintain current production process

- Reduce maintenance downtime and cost associated with special housekeeping

- Additive meets U.S. Food & Drug Administration (FDA) requirements for incidental food contact

GLASSIL® FS

Features and Benefits

- Made from feldspathic silica with 0.0130% iron content, 8.0% alumina content

- Perfect for flat, container glass and fiberglass applications

- Consistent, in-spec sand with stable chemistry

GLASSIL® Li

GLASSIL Low Iron glass sand is produced from an extremely high-purity crystalline silica sand. Unique deposit chemistry is further enhanced by wet processing and chemical flotation to offer glass manufacturers a highly refined source of silicon dioxide.

Consistently low levels of iron and other refractive elements also offer the advantage of a more uniform batch chemistry, for greater control without additions over critical quality parameters like viscosity, color and clarity.

Chemistry and uniform consistency make GLASSIL Li ideally suited to optimize batch economics in the production of flat and structural glass, specialty container glass, tableware and decorative wares and silicates.

Features and Benefits

- Made from extremely high-purity crystalline silica

- Uniform batch chemistry for greater control and consistency

- Ideal for production of flat and structural glass specialty container glass, tableware and decorative wares and silicates