Silica Sand

Most commonly known as quartz, crystalline silica, monocrystalline quartz

WHAT IS

Silica Sand?

Silica sand is a naturally occurring granular material composed of high levels of silica (silicon dioxide, SiO2). It’s abundance, purity, and diverse range of applications make it a valuable and sought-after resource in a wide variety of markets such as glass, ceramics, coatings, foundry, polymers, sports and recreation, construction, water filtration and many more.

Our silica sand is as high as 99.65% quartz. It is hard, chemically inert, and has a high melting point of 3,115° F (1,713° C), making it ideal for various applications.

We mine and process our silica sand as both whole and ground silica, and we offer our silica sand products in various ways:

|

|

|

|

|

|

|

|

PHYSICAL AND CHEMICAL PROPERTIES

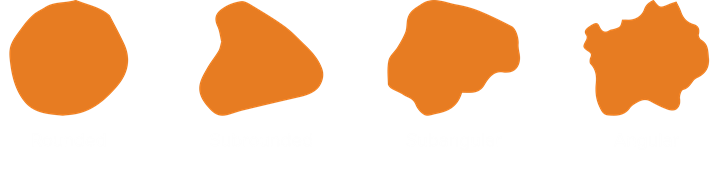

Our products require tight tolerances and qualification by the customer to ensure specifications are met on chemistry composition and grain particle distribution. The particle size of silica sand can vary from very fine to coarse, depending on its intended use. Silica sand is sourced at our mines in shapes from round to angular (Grain size distribution, shape, mineralogy, and chemistry vary by mine location).

WHERE DOES SILICA SAND

Come From?

North America has vast deposits of silica sand, with significant sources found in regions like the Intermountain West, Midwest, the Great Lakes area, and the southern parts of the United States. Our geology and mine planning teams play a vital role in procuring and developing quality mineral deposits so Covia and our customers have access to consistent, reliable products for their high-value applications now and into the future.

Covia currently has 27 silica sand mining plants in North America which are strategically located within geological formations that contain extensive deposits of high-quality silica sand such as Ordovician St. Peter Sandstone, Devonian Oriskany Sand, Tertiary-Miocene Pinehurst Sand, Cambrian Jordan Sandstone, Cambrian Galesville Formation, Ordovician Oil Creek Sandstone, Cambrian Cairnside (Potsdam) Sandstone, Eocene (Tertiary) Carrizo Sandstone and many others.

With such a diverse portfolio of silica sand deposits spanning from Canada to Mexico, our silica sand can exhibit variations in its color, grain size, roundness, sorting, purity, and other physical properties. For example, the sand chemistry, defined as the composition, structure, and trace minerals, depends on the geologic formation. The formation also impacts the trace elements, including iron oxide, aluminum oxide, calcium oxide, titanium oxide, magnesium oxide, potassium oxide, and sodium oxide. Covia is recognized for our outstanding, proprietary processing methods which can substantially remove detrimental trace minerals from our products, based on our internal quality management standards.

Planning /

Geology

Let’s start at the beginning when the mineral is still in the ground. Covia has 50 years’ mining experience that leaves the earth in similar condition to when we first encountered the site. Our geology team gets things going with a mineral formation acquisition study. We drill and log the formation, applying geologic modeling and statistics. The team applies sophisticated 3D modeling software to simulate the mineral deposit’s physical and chemical characteristics.

These 3D models are turned over to the mine planning team whose job is to develop the best scenarios for extracting the mineral from the ground. They work with other departments at Covia to consider community and environmental impacts as part of their assessment. The original 3D models are also used by each mine team to optimize the mining process, which includes a flow chart customized for each plant to create the purest product with the least trace minerals by applying our internal quality management standards.

Think of us as your 8-step process industrial minerals experts. With a quality-control check at each step of the way, we …

HAVE YOU EVER WONDERED HOW SILICA SAND IS MINED?

Join us on this educational and eye-opening virtual tour of one of our mining plants located in Chardon, OH where you'll gain unique insights on how we create high-quality silica products that are used in everyday life. Along the way, meet the team that ensures product quality at every step of the mining process.

Applications /

Markets

Related

Blog Posts

Would you like to know more about

Covia’s silica sand?