High-Clarity Antiblock Additive for Films

MINBLOC® HC Series

MINBLOC® HC High-Clarity Antiblock additive imparts antiblocking functionality without diminishing critical optical, mechanical, or structural properties in the wide range of high-clarity packaging films.

Product Highlight

MINBLOC HC High-Clarity Antiblock additive, which is nepheline syenite, is produced from one of the largest and most consistent high-purity ore reserves located in Blue Mt. Ontario Canada. A unique all-natural sodium-potassium alumino-silicate mineral that is silica deficient by mineralogical classification does not require any silica-related labeling.

MINBLOC HC additives are chemically inert, non-absorptive which doesn’t interfere with other polymer additives. This optimizes the performance of slip, antioxidants, stabilizers, colorants and other processing aids. Suitable for either masterbatch compounding or direct additions to film grade resin systems, MINBLOC HC is easy to handle and disperse which translates into higher throughput.

Mineral:

Nepheline syenite (Blend of three feldspars: albite, nepheline and microcline)

Product category:

Mineral antiblock

Applications:

Food and beverage packaging, medical packaging, plastic agricultural greenhouse films and technical films

Industry's best clarity and lowest haze values

With a refractive index that is nearly identical to that of most polymer resins, MINBLOC HC operates transparently within the polymer mix without diminishing critical structural or mechanical properties.

Excellent antiblocking performance

MINBLOC HC grades deliver an excellent balance in both antiblocking and optical properties.

Narrow particle size distribution

Easier to handle and allows for higher masterbatch loadings.

Enhanced thermicity in agricultural films

Accelerates growth by transmitting greater amounts of photosynthetically active radiation (PAR) and reduces energy cost.

Regulatory compliance

FDA-approved for up to 50% by weight in the final product; No reportable free crystalline silica, does not require silica-related labeling.

Lower oil absorption

Chemically inert, allows synergy with other additives. As a result, customers are able to achieve optimal formulation designs.

Stay up to date with current certifications

*Applicable only for Covia's Blue Mountain nepheline syenite (Blue Mt. ON, CAN deposit)

Authorized for food contact applications by the U. S. Food and Drug Administration as a pigment dispersant and filler in all types of food contact polymers and can be used at up to 50% by weight of the polymer.

Complies with Restriction of Hazardous Substances (RoHS).

Complies with Coalition of Northeast Governors (CONEG).

Kosher | Pareve – Except Passover.

EU Plastics Regulation No. 10/2011, as amended, explicitly cleared for use in all food-contact plastics without limitation (FCM No. 684).

As a naturally occurring, chemically unmodified mineral, nepheline syenite is exempt from REACH registration and is automatically included in the US, Canada, EU, Australia, Korea, Japan, China, and the Philippines chemical inventories.

Included on Japan’s Positive List (PL) maintained by the Japanese Ministry of Health, Labor and Welfare (MHLW) and cleared at loading levels up to 50% in all plastics with no other restrictions.

China’s National Health Commission (NHC) approved for use in all plastics at levels up to 50% with no other restrictions.

Product Overview: MINBLOC HC Advantages

Regulatory Compliance Overview: Safety & Regulatory Brief

Technical Bulletin: MINBLOC HC Advantages in Agriculture Films

Technical Bulletin: Effects of Particle Size Distributions (PSD) on Performance Properties of Polyolefin Films

White Paper: Nepheline Syenite as the Smart Alternative to Crystalline Silica Fillers in Silicone Elastomers

Editorial Article: Film Manufacturers Can Optimize Their Additive Package for Less Interference.

Energy Comparison: MINBLOC HC's Operational Sustainability

THE INDUSTRY'S BEST CLARITY, GLOSS, AND HAZE VALUES WITH SUPERIOR ANTIBLOCKING

MINBLOC HC high-clarity antiblocking additive is made of nepheline syenite and used in clear or opaque film applications. Due to its unique and distinctive combination of particle morphology, surface chemistry and refractive index, MINBLOC HC additive delivers excellent antiblocking performance, superior clarity, gloss and lower haze values in packaging grade flexible films without diminishing critical structural or mechanical properties.

With a refractive index that is nearly identical to that most polymer resins, MINBLOC HC operates transparently within the polymer mix. This exclusive optical property has become the standard for high-clarity films.

- Excellent aniblocking efficiency

- Industry’s best clarity and haze values

- Double classification creates a unique narrow particle size distribution

- High loadings possible with stable melt index (MI) because of almost no fines

Product Portfolio

![]()

Engineered for thin films

Less than 15 microns thick

98% of particles are below 10 microns

![]()

Engineered for films

Thickness between 1 – 4 mil

70% of particles are between 5 and 15 microns

![]()

Engineered for thicker films / Agricultural films

Thickness greater than 4 mil

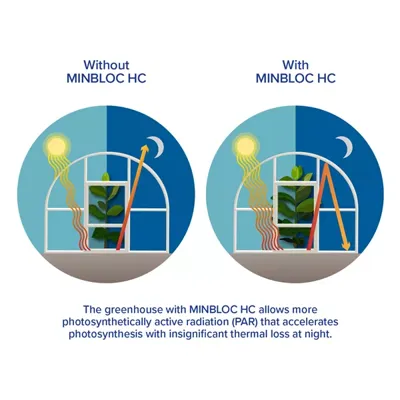

FILL GREENHOUSES WITH MORE LIGHT AND HEAT

No other plastic agricultural greenhouse film outshines MINBLOC HC’s optical and thermal properties. With a refractive index which closely matches that of polyethylene resins, MINBLOC HC additives improve light transition by maximizing the transmittance of photosynthetically active radiation (PAR) to accelerate plant growth. At night, due to strong infrared reflection properties, MINBLOC HC captures and retains thermal energy by reflecting much of the heat back into the greenhouse. This retained thermal energy increases night temperatures inside the greenhouse for optimal growth, extends the growing season and reduces space-heating requirements.

- Enhances crop protection: optimizes growth with minimal fluctuations in temperature

- Accelerates growth: transmits greater amounts of photosynthetically active radiation (PAR)

- Reduces energy cost: retains more heat inside the greenhouse compared to other mineral IR absorbers

- Extends film service life: nonreactive chemistry with low iron minimizes catalyzed photodegradation

GROW YOUR BUSINESS WITH A SAFER, HIGH-CLARITY MINERAL ANTIBLOCK

MINBLOC HC is authorized for food-contact applications by the U. S. Food & Drug Administration (FDA) as a pigment dispersant and filler in all types of food-contact polymers. This additive can be used up to 50% by weight of the polymer.

Nepheline syenite, with non-reportable levels of free crystalline silica, is preferred mineral in polymers to meet strict OSHA requirements for workplace safety. MINBLOC HC does not require any silica-related labeling.

FDA approved for indirect food contact applications up to 50% by weight.

No detectable levels of free crystalline silica.

OUR LAB IS YOUR LAB

You can think of us as an extension of your R&D team. Our lab is your lab to enhance value by solving your manufacturing challenges and customizing polymer solutions, all part of the team’s day-to-day expertise. Here, in our lab, we continue to expand the knowledge base of nepheline syenite, microcrystalline silica, and air-floated kaolin to prove the technical advantages of our functional fillers compared to other minerals and to further your plastic product proficiency.

Related Stories

Contact Covia today at 1.800.243.9004 or Sales@CoviaCorp.com, or click to fill out this form