Functional Mineral for Plastics and Elastomers

HIFILL® N

HIFILL® N, which is nepheline syenite, offers the optimal balance of physical, optical, and mechanical properties that enrich the final product’s durability. Your customers can rely on improved color stability, UV, scratch and mar resistance. HIFILL N also meets all regulatory requirements as an FDA-approved functional filler with non-reportable free crystalline silica.

Product Highlight

HIFILL N is made of nepheline syenite, which is a unique all-natural sodium-potassium alumino silicate mineral that is silica deficient. This mineral is responsibly mined from one of the largest and most consistent high-purity ore reserves located in Blue Mt. Ontario Canada. HIFILL N additives are available in ultrafine, precisely controlled particle size distributions for optimum performance. HIFILL N allows for formulation and processing cost reduction while not adversely impacting the products’ physical properties and durability.

Mineral:

Nepheline syenite (Blend of three feldspars: albite, nepheline and microcline)

Product category:

Functional filler, pigment, extender

Applications:

Excellent functional filler in wide variety of commodity resins and applications

Superior weatherability

Extended durability as result of superior photochemical stability and improved color fade resistance relative to calcium carbonate and talc.

Improved physical properties

HIFILL N has been used to improve scratch and mar resistance.

Regulatory compliance

No reportable free crystalline silica, improved industrial hygiene, safer solution - does not require silica-related labeling; FDA-approved for up to 50% by weight in the final product.

Lower oil absorption

Chemically inert, allows synergy with other additives. As a result, customers are able to achieve optimal formulation designs.

Improved dispersion color extension

Transparent, color neutral which allows for optimum usage of darker pigments and helps with pigment dispersions.

Stay up to date with current certifications

*Applicable only for Covia's Blue Mountain nepheline syenite (Blue Mt. ON, CAN deposit)

Authorized for food contact applications by the U. S. Food and Drug Administration as a pigment dispersant and filler in all types of food contact polymers and can be used at up to 50% by weight of the polymer.

Complies with Restriction of Hazardous Substances (RoHS).

Complies with Coalition of Northeast Governors (CONEG).

Kosher | Pareve – Except Passover.

EU Plastics Regulation No. 10/2011, as amended, explicitly cleared for use in all food-contact plastics without limitation (FCM No. 684).

As a naturally occurring, chemically unmodified mineral, nepheline syenite is exempt from REACH registration and is automatically included in the US, Canada, EU, Australia, Korea, Japan, China, and the Philippines chemical inventories.

Included on Japan’s Positive List (PL) maintained by the Japanese Ministry of Health, Labor and Welfare (MHLW) and cleared at loading levels up to 50% in all plastics with no other restrictions.

China’s National Health Commission (NHC) approved for use in all plastics at levels up to 50% with no other restrictions.

Product Overview: HIFILL N Advantages

Regulatory Compliance Overview: Safety & Regulatory Brief

Case Study: How Minerals Affect Color Fade

Technical Bulletin: Safer Alternative as a Functional Filler in Silicone Elastomers

White Paper: Nepheline Syenite as the Smart Alternative to Crystalline Silica Fillers in Silicone Elastomers

WIN WITH GREATER WEATHERABILITY

Nepheline syenite, with exceptional weathering quality, has been the functional filler of choice in architectural paints for three decades. Now, Covia is documenting the same success in plastics and elastomer applications. Compared with calcium carbonate, nepheline syenite has superior final-product UV resistance with considerable photochemical and abrasion advantages.

Covia R&D showed that nepheline syenite supports lower UV stabilizer while maintaining weathering durability after 7,000 hours in a UV tester.

- Color fade resistance was nearly three times that of calcium carbonate without a negative additive effect. This performance is identical in stabilized and non-stabilized systems.

- HIFILL N, a flowable, non-hygroscopic mineral whose low moisture increases extruder output, improves color characteristics to create higher-value products that are optimized for light stabilizers.

SEE THE DIFFERENCE

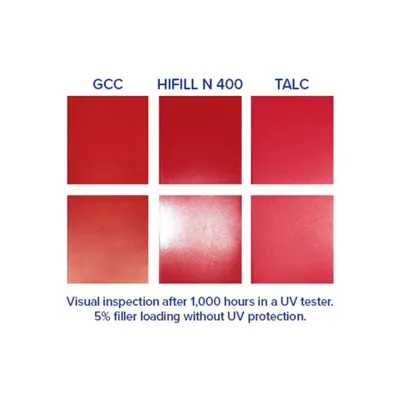

In a separate experiment, the R&D team proved nepheline syenite’s superior weatherability again, this time compared with calcium carbonate and talc. After 1,000 hours in a UV tester, the sample formulated with HIFILL N 400 is as good as new compared with ground calcium carbonate and talc. All test samples were made at a 5% wt loading in a polypropylene copolymer resin.

GROW YOUR BUSINESS WITH THE SAFER FUNCTIONAL MINERAL

Meet OSHA regulations with HIFILL N - the industry’s safest HS&E profile with no detectable level of free crystalline silica.

Made from nepheline syenite, HIFILL N is the crystalline silica-free alternative to ground or microcrystalline silica mineral fillers typically used in silicone elastomeric applications. Formulators have been adopting HIFILL N due to stricter OSHA regulations on respiratory crystalline silica (RCS). No labelling is required for plastics and elastomers products dusted with HIFILL N. This safe polymer additive is also FDA approved for indirect food-contact applications up to 50% by weight. Besides these safety factors, customers are switching formulas to HIFILL N from crystalline silica because of the similar high dielectric resistance, thermal conductivity, and compressive strength with easy masterbatch processing.

No detectable levels of free crystalline silica, improved industrial hygiene.

FDA approved for indirect food contact applications up to 50% by weight.

OPTIMIZE FORMULATION COST WITH GREATER ADDITIVE PERFORMANCE

Chemically inert, nepheline syenite offers superior performance and longer service life in demanding applications with reduced formulation cost. Nepheline syenite’s synergy accepts a lower amount of expensive UV stabilizers, lubricants, heat stabilizers, and other additives, saving money.

The lower oil absorption could also translate into minimal interference with other additives. The unique combination of low oil absorption and particle morphology enables higher loadings in masterbatches.

The transparent, color-neutral functional filler supports color extension in pigment dispersions. Outstanding purity and low tint strength preserve colorant integrity while heightening pigment dispersion. Lower pigment loading can be achieved while maintaining the same color strength to reduce formulation cost further.

- Formulation cost savings could be enabled by its transparency and low oil absorption

- Does not interfere with other additives

OUR LAB IS YOUR LAB

You can think of us as an extension of your R&D team. Our lab is your lab to enhance value by solving your manufacturing challenges and customizing polymer solutions, all part of the team’s day-to-day expertise. Here, in our lab, we continue to expand the knowledge base of nepheline syenite, microcrystalline silica, and air-floated kaolin to prove the technical advantages of our functional fillers compared to other minerals and to further your plastic product proficiency.

Related Stories

Contact Covia today at 1.800.243.9004 or Sales@CoviaCorp.com, or click to fill out this form